Advanced Fuel Consumption Measurement Technology Enables Pioneering Engine Research at Loughborough University

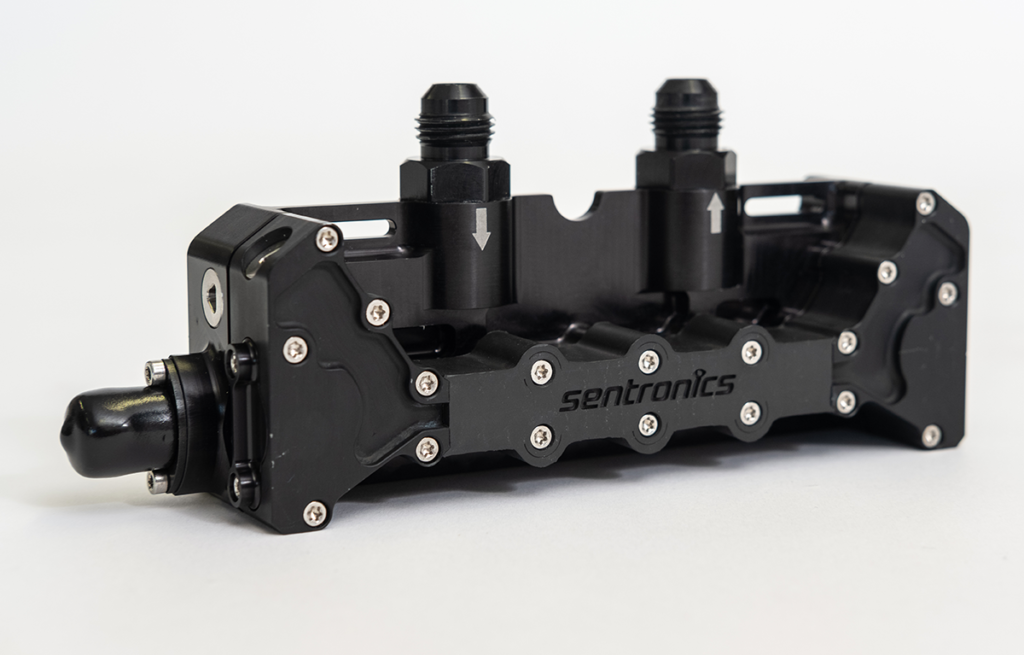

Sentronics’ FlowSonic fuel flow meter provides critical data to Loughborough University’s Automotive Engineering Research team, enabling a better understanding of vehicle engine dynamics, fuel economy and emissions.

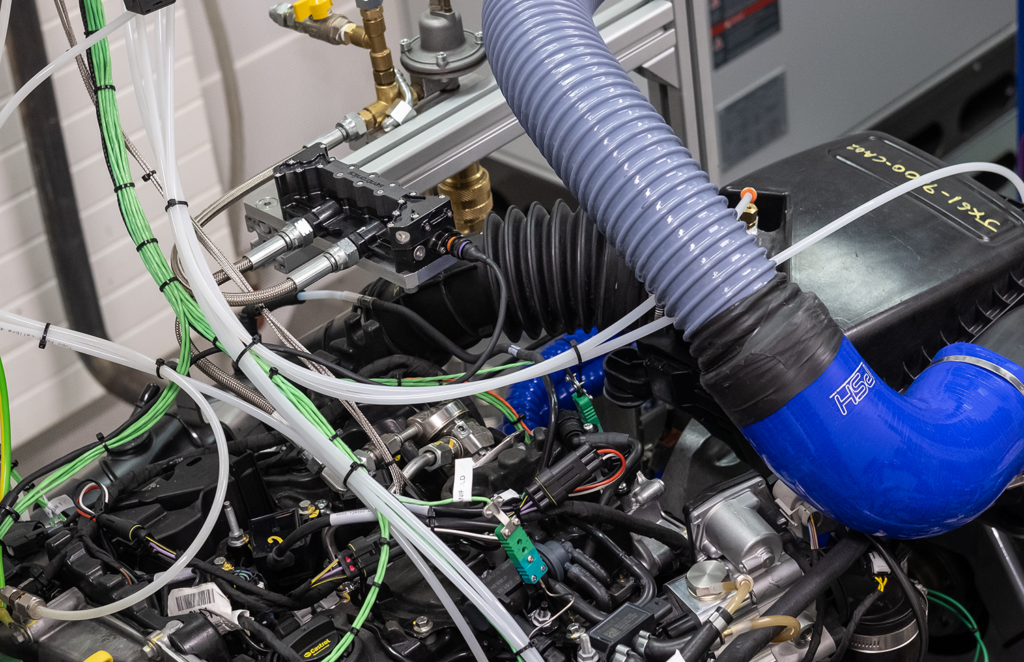

At Loughborough University, PhD Research Associate Tom Childs’ lab is engaged in advanced modelling of dynamic and transient performance in the drive cycle, and recently added the Sentronics FlowSonic LF ultrasonic fuel flow sensor to their suite of tools for measuring flow behaviour, alongside their existing AVL and Cambustion equipment.

The Loughborough team’s work centres on deconstructing a given drive cycle into the engine’s various operating modes and the transitions between them, which routinely include short-lived transient flow events. The engine and all its actuators are then operated over their respective ranges with the aim of capturing the engine response throughout its entire performance envelope.

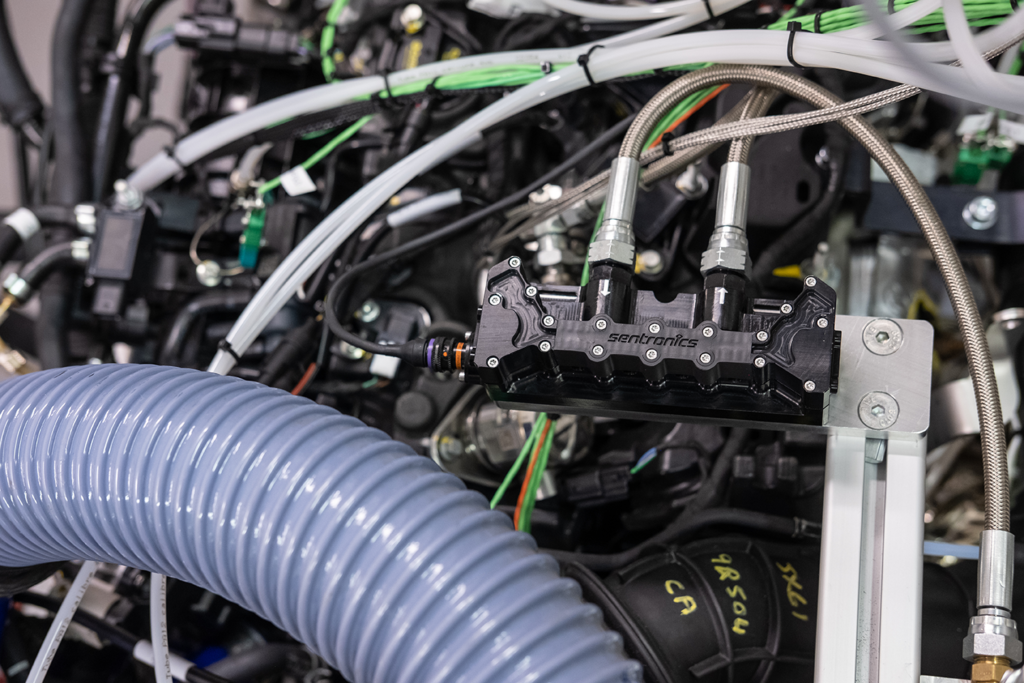

The FlowSonic offered Loughborough a single device that can be used on the test rig and also installed in the vehicle engine bay to measure fuel flow under the ever-changing driving conditions of the real world. Childs saw a need to improve his group’s modelling to help OEMs meet the demands of RDE testing and, more generally, optimise engine control and calibration to reduce consumption and emissions. The decision to adopt the FlowSonic was reinforced by that fact that one of the university’s OEM partners uses the sensor in its own bench and road testing and that it is supplied with a UKAS-accredited calibration.

“The FlowSonic has taken the resolution, accuracy, and repeatability of our models to a new level, transcending the limitations of steady-state lab testing. We simply couldn’t do the work we are doing now without it, explained Childs. “For example, its extremely high response rate (up to 2.2 kHz) actually allows us to see individual injector pulses. The small size lets us measure closer to the fuel rail than any other technology, all but eliminating a substantial source of error. The FlowSonic even highlighted deficiencies in our dyno set-up – notably temperature variations affecting fuel density – which has prompted upgrades to our test cell.”

“There are significant on-vehicle advantages as well. Fitting the FlowSonic in the engine bay is quick and easy because it’s so small and unaffected by orientation and. unlike other on-board equipment, its compactness and light weight means there’s no distortion of vehicle performance. Our work also benefits from the sensor’s minimal pressure drop and reliability thanks to the absence of moving parts.”

“Working with the FlowSonic gives us better information in less time at lower cost,” Childs concludes. “It provides a powerful tool for learning how to get the most out of the internal combustion engine while electric drivetrain technology develops and matures.”

For more information about FlowSonic and how the technology is being used to improve understanding of real-world fuel consumption of internal combustion engines, click here.